The Zhongwei Centralized Monitoring and Management Cloud Platform launched by Zhongwei Intelligent can monitor smart terminals and computer room equipment distributed in different areas, such as video network control boxes, UPS power systems, batteries, switching power supply systems, precision air conditioning, and computer rooms. Fully centralized management of environmental temperature and humidity, smoke and fire protection, access control management, video monitoring, etc.; real-time monitoring of the status parameters and operation of various equipment, intelligent control and maintenance of related equipment, and the ability to use voice, e-mail, mobile phone SMS, etc. Alarm information is sent in various ways to inform the person in charge of maintenance and management in time. Compared with similar products and systems, the super intelligent measurement and control management platform has led the market in similar products and functions. The super-intelligent dynamic environment monitoring platform system has a simple, easy-to-use, sufficient and safe design concept, which can be widely used in finance, communications, power, transportation, military, enterprise, education, agriculture, aquatic products...

You can view the total number of real-time online analysis videos, video online rate, timely repair rate of faults, average repair time, video drop list, point alarm status; you can analyze various alarm abnormalities and historical trends globally.

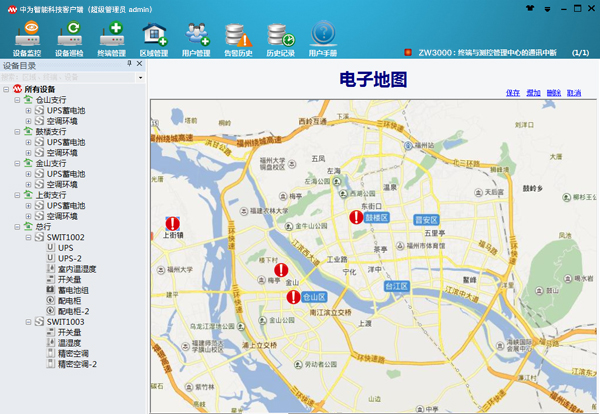

According to the latitude and longitude, the distribution of each monitoring point is directly marked on the map, and the basic information, equipment information, and working status of each point are directly reflected, including normal, abnormal, offline, etc.

You can learn about the power supply, ambient temperature and working status of the device at a single point in detail. You can remotely control the device to power off and restart, and set device parameters.

Support statistics on the current status of equipment by equipment type, and export equipment list.

Support voice notification alarm information, support to set the alarm level of various alarms, and set the processing time of different alarms by region.

Support automatic dispatch and manual dispatch, and record the work order processing process in detail.

Support statistics on the failure rate and online rate of the cameras under the jurisdiction of time, brand, region and other conditions, and provide a variety of statistical report display methods, such as histograms or line charts; able to count failure repair time, timely repair rate, and timely repair rate.

Support batch firmware upgrades to front-end equipment boxes, support offline upgrades, resumable transfers, and version automatic matching upgrades; support development interfaces or communication protocols to connect to third-party platforms; support Hikvision operation and maintenance platform docking.

Support the municipal bureau and provincial multi-level platform summary management.

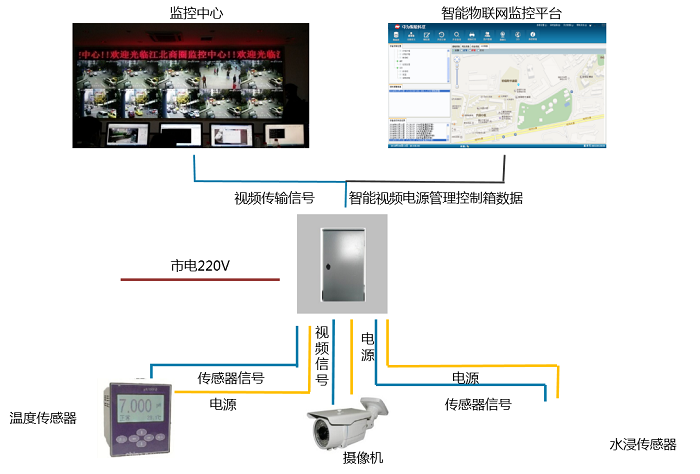

The ZW3000 platform includes the measurement and control of UPS, batteries, fuel gauges, engine sets, precision air conditioning, switching power supplies, access control, temperature, temperature and humidity, switching values, video and other important equipment. Corresponding monitoring modules can be added according to the actual equipment of the required measurement and control sites to save corresponding resources.

users can customize a set of their own window layout according to their own software usage habits, which is flexible.

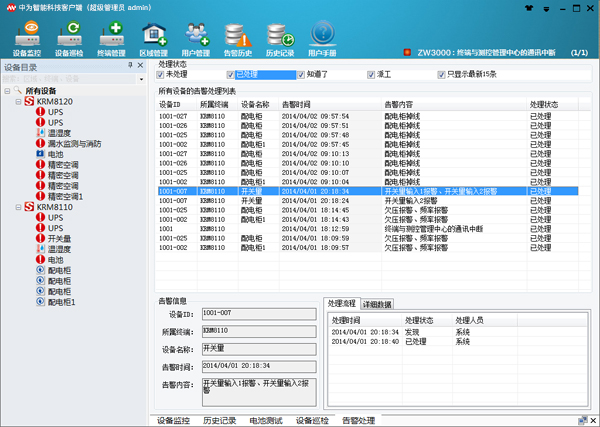

when equipment faults and abnormal parameters are found, multimedia animation, voice, telephone, short message and other alarm methods are adopted to record historical data and alarm processing.

Through the graphical graphical interface, the real-time data, working status and control results of the device can be visually displayed.

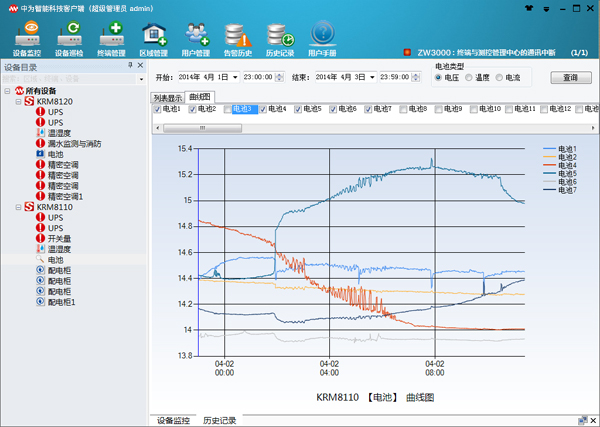

Histogram and data visually display the current status of the battery. Curves and data record the changes in voltage, current, and temperature of the battery during charging and discharging. Analyze the hysteresis of the charging and discharging process of the single battery to find the battery damage in time. To prevent the UPS from providing sufficient backup power supply time due to battery damage.

The user sets the battery self-test time according to the task, and regularly conducts a safe self-test on the battery regularly. Accurately check the health status of each battery. Charge and discharge battery data automatically records the data of the battery in the charge and discharge state. A set of data shows the change of the single battery curve analysis to determine the quality of the battery. Manually find the battery with lagging performance.

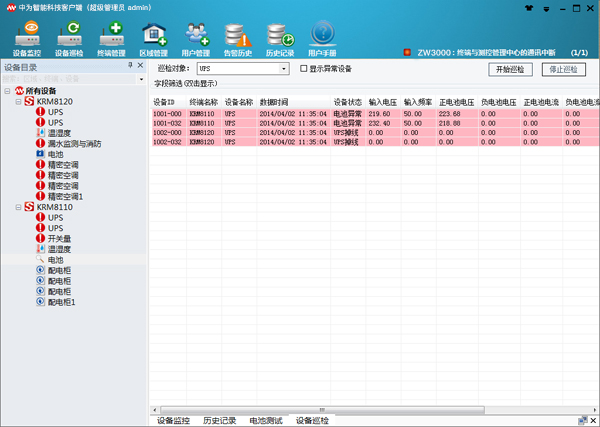

one-key operation completes automatic inspection, generates inspection reports for each device, and provides flexible inspection and maintenance reports. Administrators can easily and quickly complete inspection work, greatly improving work efficiency, Reduce the work intensity of maintenance personnel, reduce manual inspection and maintenance costs.

Super intelligent measurement and control terminal is connected to the center normally, and all devices are added through one-key operation.

set the alarm level (emergency, important, and general alarm). When different levels of alarms occur at the same time, the management personnel can focus on them in order.

detailed record the handling process of each alarm, clarify the person responsible for the alarm handling, the scope of responsibility and the accurate time, which is convenient for maintenance management and safety responsibility management.

When the alarm device resumes normal operation, it will automatically process the previous alarm of the device without manual operation. If an alarm is issued when the mains power is interrupted, and the mains power returns to normal, the system will automatically record the alarm information and clear the alarm. No user operation is required, greatly reducing the user's work.

files related to the device can be uploaded to the server to facilitate subsequent management.

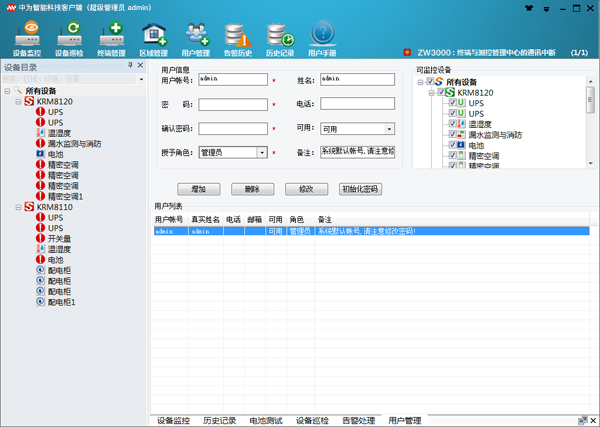

The operator's authority management is meticulous, and the super administrator can assign devices to different users and user management authority. The responsibility for ensuring the security of platform management and equipment monitoring and management is clear.

the management personnel draws the equipment distribution map on the electronic map according to the equipment distribution of the computer room, and marks the icons of various video images and sensors. When the software is running, the dual screen is displayed as a video window and an electronic map window. On the electronic map window, you can easily find the location of each video point and sensor, and you can easily choose to view the data of the sensor. When an abnormality occurs, you can quickly prompt the abnormal location on the electronic map.